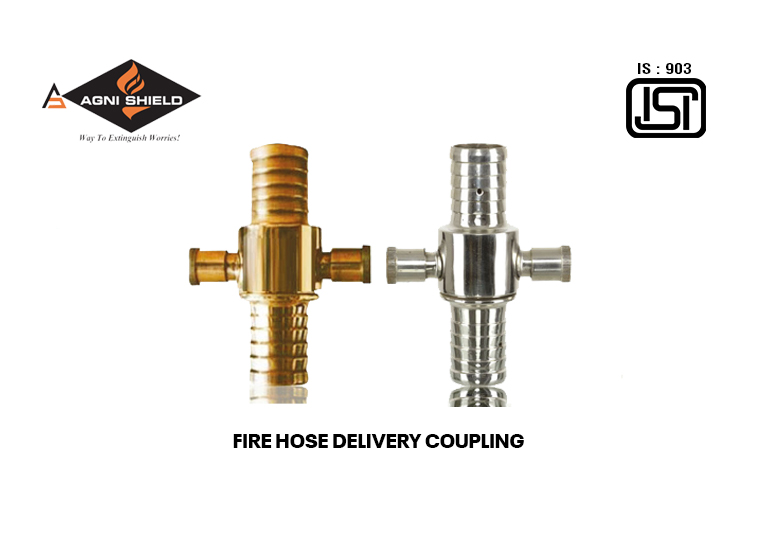

Fire Hose Delivery Coupling

Product Specification

- Type: Single jacket / Double jacket / Rubber-lined / Synthetic-lined

- Working Pressure: 8 bar to 20 bar

- Temperature Range: -20°C to +60°C

Product Description

A fire hose delivery coupling helps to connect and disconnect the hose from the water source quickly and conveniently. It maintains a secure connection to prevent leaks and ensure connection reliability. Made from highly durable, heat-resistant materials, our fire hose couplings can withstand pressures from 8 bar to 20 bar and temperatures up to 60+ degrees Celsius.

Additionally, depending on the type, fire hose couplings can be used for a wide range of applications. This flexibility is another significant advantage of fire hose couplings. As the leading hose reel drum manufacturers in India, Somya Pyrotek Services Pvt. Ltd. offers high-quality fire hose delivery couplings to ensure rapid hose deployment during emergencies.

Applications Area of Fire Hose Delivery Coupling

- Fire stations

- Residential buildings

- Commercial complexes

- Industrial facilities

- Chemical plants

- Oil and gas refineries

- Airports

- Warehouses

- Marine vessels

- Shipyards

- Railways

- Construction sites

- Hospitals

- Schools and colleges

- Shopping malls

- Hotels

- Power plants

- Mining sites

- Ports and harbors

- Public parking structures

Key Features of Fire Hose Delivery Coupling

- Leaf-proof and secure connection with a locking mechanism

- Works exceptionally well even in high-pressure conditions, crucial for fire protection systems

- Availability of different types — can be fitted with hoses of varying sizes

- Made with durable materials – Stainless steel, Aluminum, Brass, and More

- Makes it convenient to connect and disconnect the hose from the water source

- Ensures a strong connection even when exposed to consistent vibrations

- Keeps a steady water or chemical flow

- Made under strict quality guidelines for global standard compliance

- One of the most crucial firefighting hose accessories when responding to emergencies

Technical Specifications

| Hose Type | Compatible Coupling Material | Standard Sizes (mm/inch) | Working Pressure Range | Lining/Construction Details | Typical Applications |

|---|---|---|---|---|---|

| Single Jacketed | Aluminum / Brass / Mild Steel | 38 mm, 50 mm, 63 mm / 1.5”, 2”, 2.5” | 8–14 bar (116–203 psi) | Single-woven polyester jacket | Light industrial use, municipal fire protection |

| Double Jacketed | Aluminum Alloy / Gunmetal | 50 mm, 63 mm / 2”, 2.5” | 14–21 bar (203–304 psi) | Two-layer woven polyester for higher strength | Heavy-duty firefighting, high-pressure industrial systems |

| Rubber Lined | Aluminum / Stainless Steel / Brass | 38 mm, 50 mm, 63 mm / 1.5”, 2”, 2.5” | 10–17 bar (145–246 psi) | Natural/SBR rubber tube bonded to jacket | Chemical plants, refineries, and high-abrasion environments |

| Synthetic Lined | Aluminum / SS304 / SS316 | 38 mm–75 mm / 1.5”–3” | 12–20 bar (174–290 psi) | TPU / EPDM / synthetic polymer inner lining | Marine, aviation, industrial fire safety, saltwater use |

Significant Benefits of Using a Fire Hose Delivery Coupling

The fire hose delivery coupling by Somya Pyrotek Services provides high-grade fire safety to residential, commercial, and industrial spaces. It offers the following key benefits:

1. Improve Emergency Response Time

When dealing with fires, time is of the essence, and quick responses are a lifesaver. Therefore, experts recommend using high-quality hose couplings in fire protection systems to ensure quick hose deployment. Couplings make it convenient and straightforward to connect the hose to the water source. Not only does this save you time, but it also ensures the connection is strong enough to withstand high-pressure water and chemicals.

2. Better Operational Efficiency

Reaching the fire source can be challenging, especially in industries or in congested residential areas. A fire hose delivery coupling connects two or more hoses, helping the fire safety department increase its operational reach. This has a significant impact on the operational efficiency and prevents time wastage. On top of that, the hose connection is leakage-free and offers a controlled water supply.

3. Ensure Safety for Fire Fighters

Industrial hoses and fire safety systems need robust security solutions to ensure the safety of brave firefighters. That is precisely why Somya Pyrotek Services provides the best fire hose delivery coupling for Industrial use, made from uncompromised-quality materials. This allows you to securely connect high-pressure hoses without the risk of equipment failure and water bursts.

4. Standardization for Compliance Regulations

Compliance with regulations is critical for fire protection systems, as it ensures the use of high-quality products. At Somya Pyrotek Services, our fire hose couplings are manufactured in ISO-certified facilities and undergo rigorous quality checks. Consequently, you get final products that offer the required fire protection.

5. Customizable Options

With Somya Pyrotek Services, you can choose between different fire hose delivery coupling types, including:

- Single jacket

- Double jacket

- Rubber lined

- Synthetic lined

Additionally, as one of the leading hose reel drum manufacturers in India, we offer you custom solutions that are designed for your particular requirements. As a result, this will help you cover every critical aspect of fire safety and get optimized fire safety solutions. We have designed and manufactured fire safety solutions for numerous clients, offering custom solutions for residential areas, hospitals, institutes, and coaching centres. Our client list contains names such as:

- HDFC Bank,

- Union Bank,

- Delhi Metro,

- Dabur,

- Indian Railways and many others.

Risks with Poor Quality Fire Hose Delivery Couplings

The table below explains all the pain points experienced by using a poor-quality fire hose delivery coupling:

| Risk | Explanation |

|---|---|

| Leakages and water loss | Unreliable sealing leads to reduced pressure and ineffective firefighting |

| Sudden disconnection | A weak locking mechanism may detach under high pressure, causing hazards |

| Burst or failure under pressure | Inferior materials can crack or deform, risking equipment damage |

| Delayed response time | Frequent adjustments or breakdowns slow emergency operations |

| Safety hazards for firefighters | Risk of injury from whipping hoses or pressure surges |

| Contamination or corrosion | Poor materials deteriorate quickly in harsh environments |

| Non-compatibility issues | Mismatched standards prevent proper connection with hydrants or pumps |

| Higher maintenance costs | Frequent repairs and replacements increase long-term expenses |

| Reduced lifespan | Faster wear and tear shortens operational life |

| Compliance issues | May fail safety inspections or regulatory requirements |

Critical Tips for Installing and Using a Fire Hose Delivery Coupling

Keep the following things in mind when installing a fire hose delivery coupling:

- Make sure you choose the fire hose coupling that matches the hose size.

- Keep the coupling clean before installation to prevent the hose from slipping.

- Double-check the connection and ensure the hose is connected correctly.

- For chemicals, use abrasion-resistant couplings.

- Align the hose and coupling in the right way.

- Test the couplings with various pressure scales before using them.

- Check the coupling for wear, tears, physical deformation, and corrosion before using.

- Perform routine checks on couplings and use the official maintenance guide.

If you have any further doubts regarding how to install a fire hose coupling or how to use them, feel free to contact our experts. They will guide you on proper procedures and help you implement appropriate fire safety measures. Contact information:

Office:

102-A, Jaina Tower -III,

A-1 Janak Puri, New Delhi

Phone Number:

+91 – 9811141246

Why Choose Somya Pyrotek Services?

With over 150 global-standard products, we have provided fire safety solutions to more than 20,000 locations. Our goal is not just to deliver fire safety systems, but to provide our clients and customers with complete fire safety solutions. One of the vital components in that process is our fire hose delivery couplings.

Manufactured with precision in ISO-certified factories, our fire hose delivery coupling ensures optimized fire safety. On one hand, they reduce emergency response time, while on the other, they provide the protection of firefighters from unexpected pressure bursts.

Another benefit of choosing Somya Pyrotek Services is our custom fire safety solutions. Our experts will consult with you to understand your fire safety requirements. Then, based on the information, they will develop highly optimized, cost-effective safety solutions.

Want to elevate your fire safety with custom solutions? Send us your requirements, and our experts will get back to you with concrete safety plans!

FAQs

A: Our product range contains the following fire hose delivery coupling types:

- Single Jacket

- Double Jacket

- Rubber-lined

- Synthetics-lined

In addition to the options mentioned above, you can choose custom hose couplings to meet your specific requirements.

A: If you are going to use an abrasive extinguishing medium, here are some coupling materials to ensure safe and corrosion-free operations:

- Stainless Steel – Highly resistant to chemical corrosion

- Brass – Strong resistance to corrosion

- Specialized Composite / Polymer Materials – Lightweight and non-reactive

Among the three options, stainless steel is considered the best. It is durable and chemically resistant.

A: Here is a step-by-step guide on how to install fire Hose Coupling:

- Inspect and clean the hose ends

- Align and connect the couplings

- Secure the lock

- Pressurize slowly

- After use, fully release the pressure before disconnecting, and clean/store properly.

A: The color code in fire hoses is crucial and helps in identifying their applications. This also allows you to choose the right firefighting hose accessories with the hose. Standard fire hose colors include red, yellow, off-white, and green.

A: Imperfect design, poor material quality, and corrosion can lead to leakage. As the reliable hose reel drum manufacturers in India, Somya Pyrotek Services provides supreme-grade couplings to prevent leakage.

A: Custom fire safety solutions and firefighting hose accessories are highly beneficial for large-scale industrial and commercial spaces. These solutions are designed to cover unique safety requirements and provide complete protection.

A: As the leading hose reel drum manufacturers in India, we offer complete fire safety solutions with a wide range of products. Our product catalogue includes Portable fire extinguishers, CO2 fire extinguishers, Water/Foam fire extinguishers, heat detectors, fire alarm panels, and more.

To know about our products or personalized fire safety solutions, feel free to contact us!